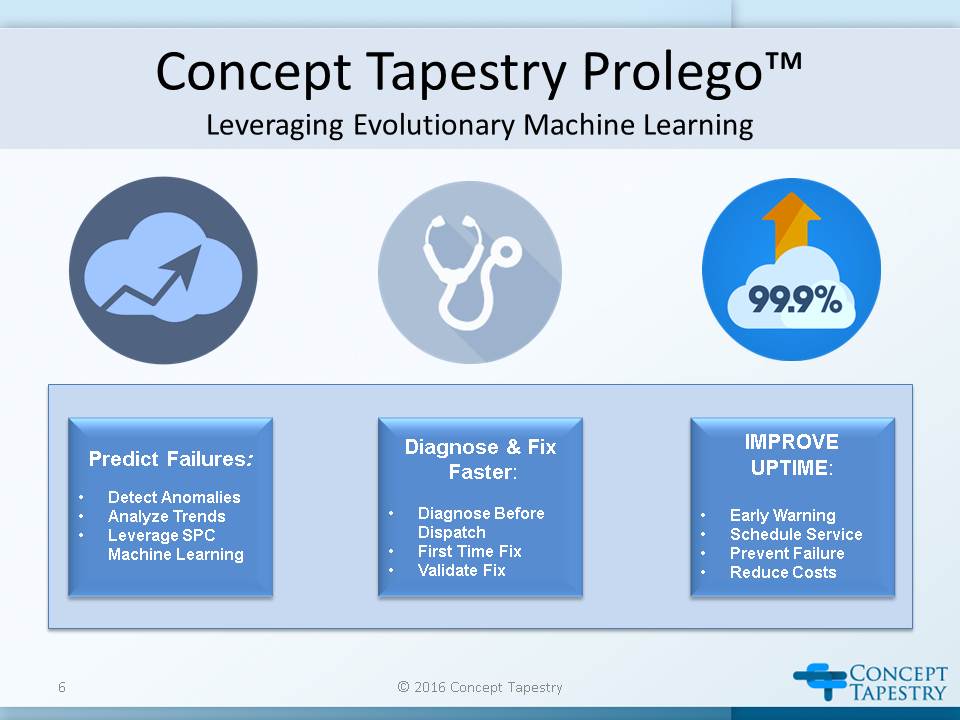

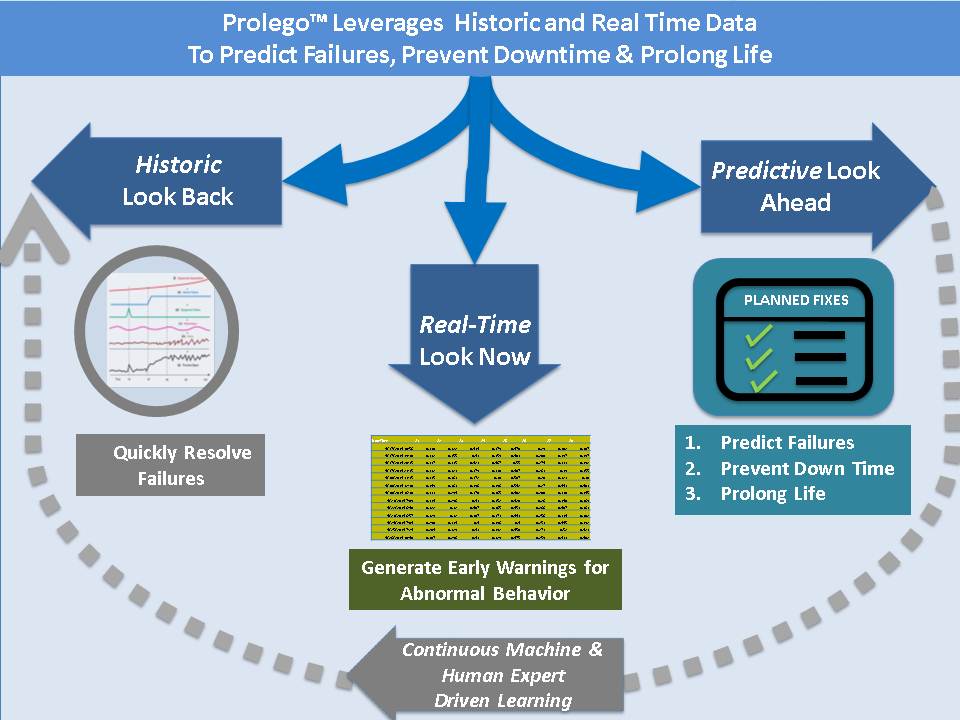

Prolego™ reduces unplanned downtime, reduces mean time to repair, improves availability and reduces the total cost of maintaining and utilizing critical medical equipment. Prolego™ links actual usage data and usage history from all connected critical equipment to provide insights into parts degradation, equipment wear-and-tear, and signal trends to provide proactive alerts and alarms that prevent failures before they occur and result in greater operational uptime.

Prolego© employs powerful machine learning algorithms to correlate equipment performance symptoms with actual failure and error history. Prolego© can anticipate and provide early warning of impending part failures and error conditions before they occur, preventing critical equipment downtime.

Prolego© works to address three commonly-encountered critical equipment situations. In cases of a downtime event, Prolego© rapidly analyzes historic data to identify the root cause of the failure so necessary repairs can be performed quickly. Prolego© also monitors the equipment post-treatment and provides early warning on developing abnormal behavior trends so corrective action can be taken to prevent downtime events. Finally, Prolego© correlates symptoms with actual failures and error conditions and learns to provide early warning and alarms on impending part failures so replacements can be ordered and installed before they cause hard equipment failures.

Prolego© learns critical parametric baselines and uses the learned baselines for recognizing equipment degradation trends and impending failure events. Real time monitoring of these parameters against the learned baseline of acceptable normal values enables Prolego© to prevent a majority of unplanned failure events into planned scheduled maintenance events.

Prolego© has been successfully deployed at several clinical sites, enabling service organizations to reduce diagnostics times by over 70%, reduce unplanned downtime by over 50%, and to transition towards cost-effective “reliability-based maintenance” practices.